BLOG

Ecommerce Inventory Management: What It Is & 5 Essential Techniques

Updated: Feb 8, 2023

Learn about the essential inventory management methods and enhance your eCommerce sales and marketing strategy.

So, you are living the dream! After months of making plans, figuring out costs, and putting in the hard graft, you have finally set up shop. You are running your own eCommerce business! Or, you may have had an online business for years…

Either way, there is one aspect of all retailer’s lives that doesn’t get the traction it needs. And that is knowing how to use inventory management methods to make your business the best it can be.

What is eCommerce inventory management?

On the most basic level, inventory management is sourcing, storing, and selling stock. It is knowing how much stock you have, how much it should sell at, where to keep it, and how long to keep it for.

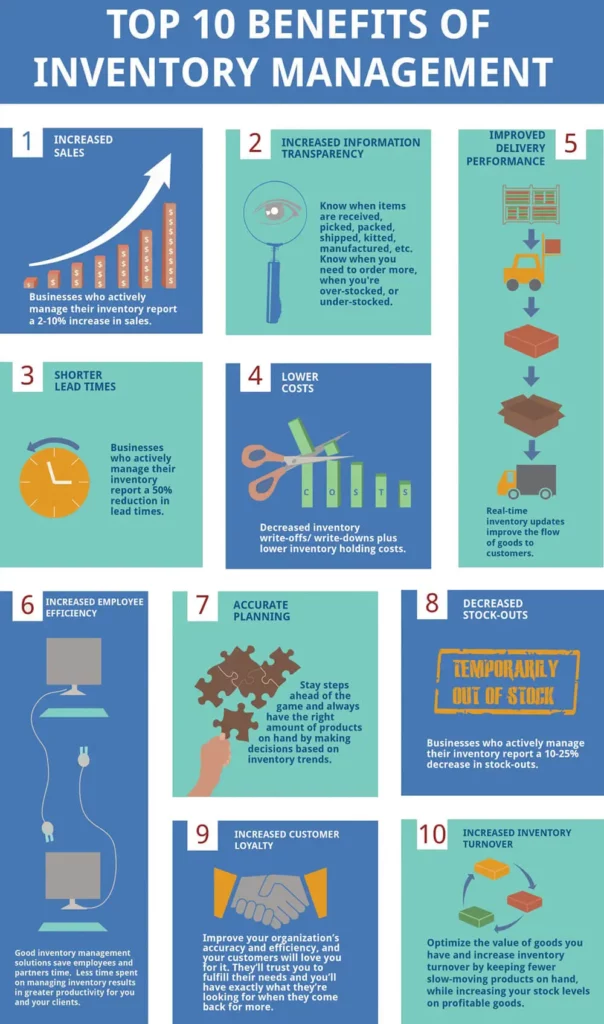

Understanding how to manage inventory is crucial for any business – large or small. It prevents waste, saves costs, and saves time. Keeping on top of supply creates more customer focus as it gives people the products they want.

Unfortunately, many businesses still lack the knowledge in inventory management best practices. Some of the biggest firms in the world have collapsed through not using the right techniques and systems.

Here are a few pointers to make sure your eCommerce store stays on top by adopting a proper inventory management system.

Understand the ins and outs of inventory management

Why you need inventory control

Inventory control doesn’t have to be complicated, but it is always important. Understanding stock levels helps you with knowing;

- When to re-order. First, you need to know when stock is running low. You don’t want to be in a position where you cannot provide products for customers. Think of it as doing a weekly shop. If you are running out of milk, you don’t wait until the carton is empty before you buy more.

- How much to re-order. Say you own an online pet shop. The squeaky carrot toys have been selling much more than you predicted. So, you need to order more of those in. Yet, you don’t want to over-order and have piles of high-pitched toys piling up in the warehouse. Managing inventory helps steady numbers too.

- How many more to order. Keeping with the toy example, if the carrot is selling well, will a squeaky tomato sell well too? Accurate inventory tracking will also help with the purchasing and success of new products.

- How long stock can stay out/in the warehouse. This is something that may seem a little obvious for things like perishables. But without proper inventory, a lot of goods may end up unaccounted for and unsold. Left either to go out of date or out of fashion.

Choosing the right inventory management software

According to Wasp, 43% of small businesses still use manual methods to manage inventory. What this really means is 43% of small firms are vulnerable to mistakes. So, having a software tool assists in avoiding chaos and human error.

However, choosing the right inventory management software is no small feat. You really have to consider the nature of your business, your company size, specific challenges and needs. GoCodes suggests asking the following questions:

- How many users will require access?

- Does the software allow for scalability as your company grows?

- Can the software integrate with other systems?

- Can they provide data migration assistance?

- Does the system allow for customized reporting?

- Are you allowed to audit the history of your inventory?

- Does the software allow you to prevent stolen, lost or misplaced inventory?

- Do you need to access the inventory management software on multiple devices?

- What is the quality of their technical support during troubleshooting?

Based on the most common criteria, you want to find software that:

- Can analyze data in real-time;

- Analyze data and optimize inventory

- Takes overstocking and understocking into account;

- Considers seasonality;

- Makes adjustments for where the product is in its lifecycle.

Using software that leverages price optimization will also be a great benefit. It will give you recommendations on when to sell at higher or lower price points, and what sells best in which season. Not only does it help you sell the stock for the best profit, but it also helps clear space for new stock.

If you still feel like you’re missing some information about all the inventory tech options, check out Brightpearl’s retail tech stack report. The report helps you understand the options that are available and the current market trends influencing them.

Having an understanding of the solutions available will speed up the process of choosing or upgrading a software tool, thus making sure your money is being spent on the right tech in the right areas.

What you need to know about auditing

Auditing is making sure that you are checking how much stock you have. Even with the best software, it’s important to do manual auditing too. It can help account for any stolen items and prevent any over or under-stocking issues.

The first way to do this is through a full audit. This usually involves counting all the stock a couple of times a year. Frankly, this method can be time-consuming and boring.

The second way is to do a partial audit. Also known as cycle counting, this is when you count items throughout the year. It checks against already recorded numbers and helps measure accuracy.

Spot checking is the third technique. This is when you randomly compare the numbers of one item to the recorded numbers in your software. It’s a good way to check that numbers are accurate.

Of course, different approaches will work better with each company. The following are a few ways that may work for you.

Types of auditing

Setting Par levels

This is also known as keeping safety stock. It’s a method that helps structure, order, and assign priority to items. It works by making sure there is a minimum amount of stock for each product. Setting a Par level is often used in hospitality. The method prevents food waste and keeps inventory healthy.

Orderly suggests that Par level is usually worked out using the following formula:

Par level = (Weekly inventory use + Safety stock) / Deliveries per week

It also suggests keeping around 20%-30% of the weekly inventory to use as safety stock.

An advantage to this technique is that staff don’t have to have as much knowledge about inventory management. They will always know the least amount to order.

First in First out (FIFO)

Also known as FIFO, the First in First out method focuses on selling older stock before anything else. This helps with the natural flow of goods. It makes it easier for record-keeping, too, as it avoids recounting old stock.

And it isn’t just food companies that need to consider this method. Whether it’s tech, clothes, or something in between, fashion dictates the quick change of many products. You don’t want to be stuck with piles of “Mom Jeans” in the back. Waiting for them to come into style for a third time so you can shift them.

Essentially, using FIFO means you can have a high rotation of stock. This keeps things fresh and prevents you from having to do massive clear-out sales.

ABC management system

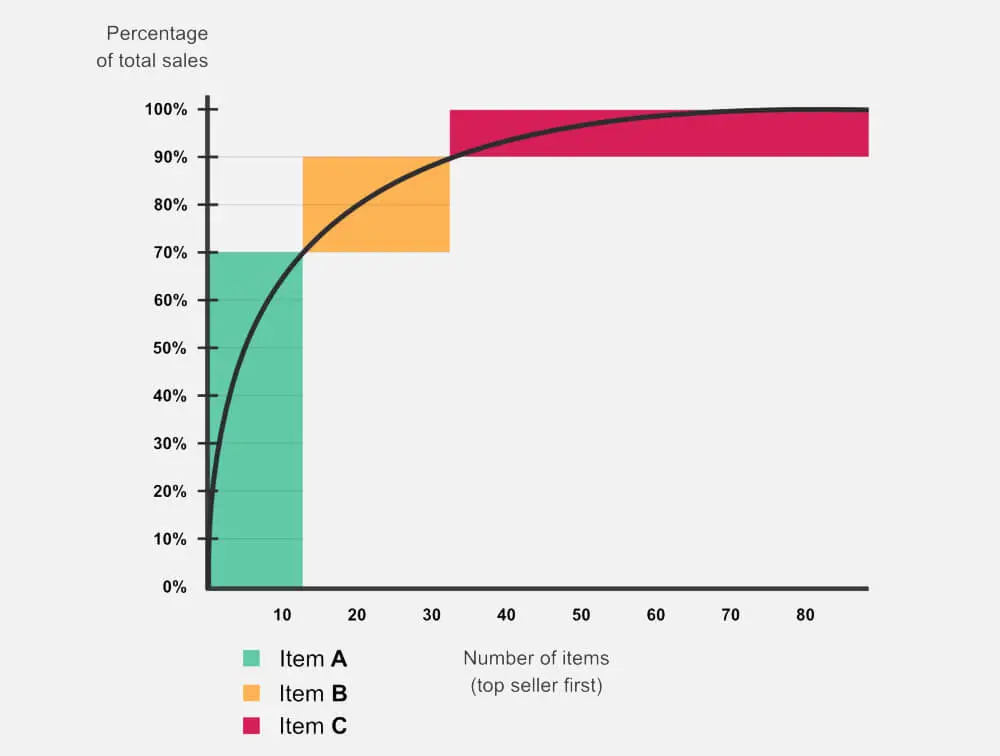

This is a really simple way of categorizing products from least to most valuable. Essentially, it’s looking through inventory and working out if each line is in the A, B, or C category. A is a highly valued product but low in quantity. B has regular products in moderate quantity, and C is low valued products in high quantity.

A provides 80% of revenue and 20% of the stock. B provides 15% of revenue and 30% of the stock. C provides 5% of revenue and 50% of the stock.

Say, for example, you own an online footwear shop. The ABC method in this scenario may look like this:

A: High-end, expensive trainers earn the majority of the sales (80%). Selling just three pairs of these in a day makes most of the income. But as they are on the pricey end, fewer people tend to buy them, so you don’t have a lot in stock (20%).

B: Work shoes are somewhere in-between with sales and stock. They get a decent amount of sales in a day but not a huge amount. They aren’t as expensive as the trainers, and are more of an essential item. So, these sales make around 15% of revenue and make up 30% of the stock.

C: Socks make the most sales in a day. So, they are 50% of the stock. Yet, although lots of these are sold, they are cheap. And so only makes up around 5% of the profit.

Working with this method enables you to focus on the products that are most profitable for you. That’s one vital element of managing a successful eCommerce business. It will help you to know which items to keep in stock.

5 essential inventory management methods for eCommerce

Finally, there are some key points to remember when using inventory management. Keeping these points in your mind will help your stock go that bit further. They will also make sure you are profiting and keeping customers happy.

1. Keep an inventory of safety stock

You never know when something unexpected may happen. Therefore, it’s important to make sure you have safety stock.

There could be many reasons you may need this. We only need to look at recent cases of panic buying to see that unexpected supply and demand happens. Keeping an inventory of the stock will make sure you prepare for anything unforeseen.

2. Balance inventory

This is as simple as not overstocking and not under-stocking. It’s about getting the balance right.

You don’t want to have so much stock you are having to liquidate. But you also don’t want to have too little stock that you have to tell a customer you don’t have the product and push away your target market. Both these can lead to loss of profit through clearance sales and bad reviews.

Having the right software and managing inventory correctly will help avoid this.

3. Use a kitting technique

Putting together stock to sell as a deal is known as kitting. E.g. Buy 2 Get 1 Free offers. It helps to get rid of any overstock at a good price. It also boosts average order value and lets customers know they are getting a great deal.

4. Look at past purchases to predict future stock

In doing this, you can create a feedback loop of understanding what stock works. You can assess the stock that needs either boosting or reducing. Tracking stock enables you to see which products are selling the best. It also helps in the assessment of yearly trends and can be done as often as you like.

5. Be smart with storage

When gathering stock to sell, it’s important to think about the physical storage of items. Whether keeping items in a spare room or a warehouse, make sure the items are easy to locate.

Keeping them at a place where you can easily pack and post them means the customer will get the item sooner. Base the location on sales and trends. Move things around now and again if you need to. Doing this will help you to keep on top of your stock and will deliver great customer satisfaction.

In conclusion

Having a great inventory management system in place can make your job so much easier. Using a mix of the right software and these techniques will make sure you are keeping on top of your inventory resulting in more profit for you. Ultimately, it means a happier customer who will keep on coming back.